FORCE CONVECTION GLASS TEMPERING FURNACE

According to the convection heating theory,we adopt special designed convection fan and thermal circulationstructure, besides,we apply some other advanced technology,all of which roll into one that speeds the glass heatingand improves efficiemcy and producs qualuy.the advantage is more distinct when processing LOW-E Glass

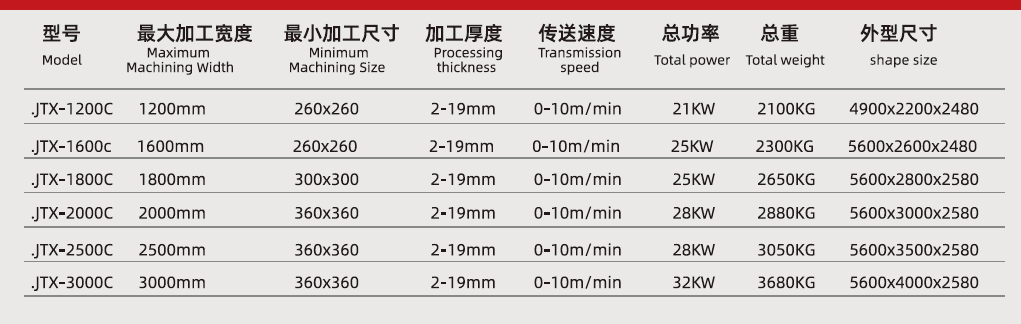

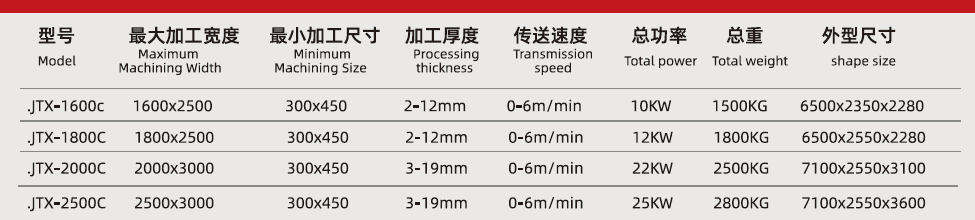

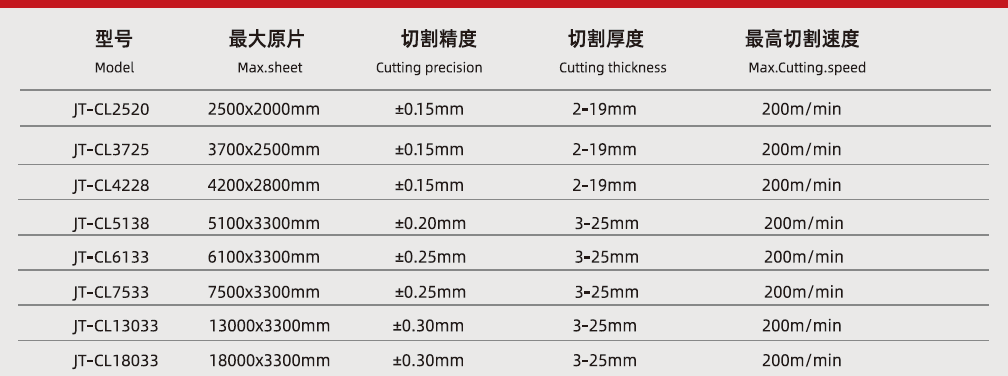

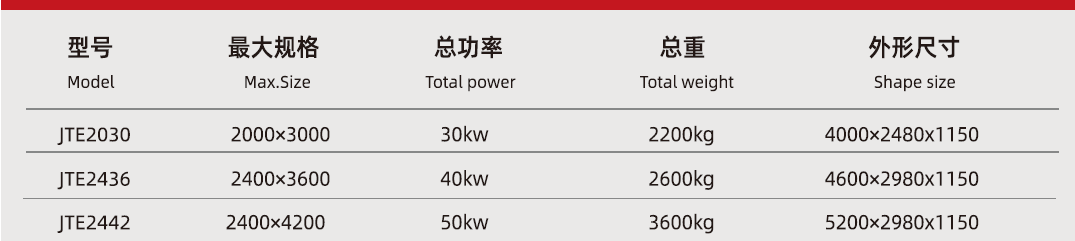

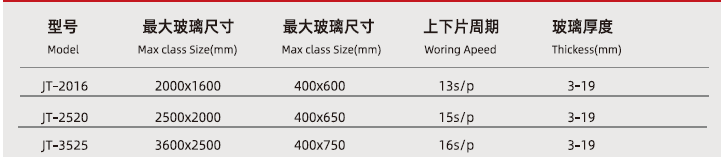

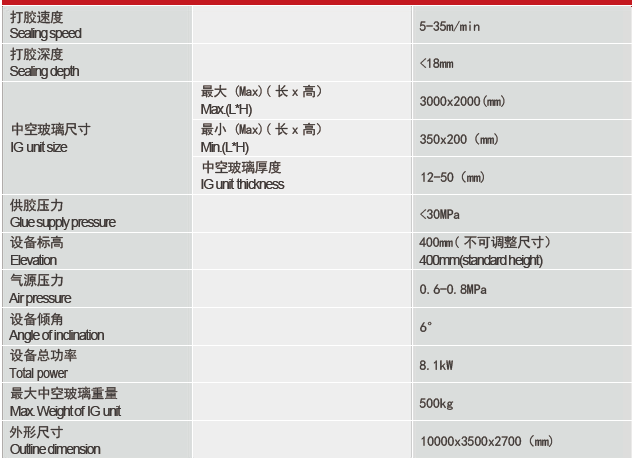

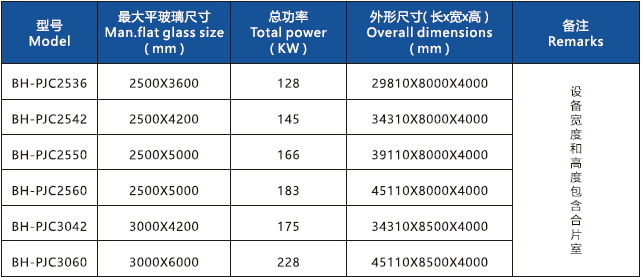

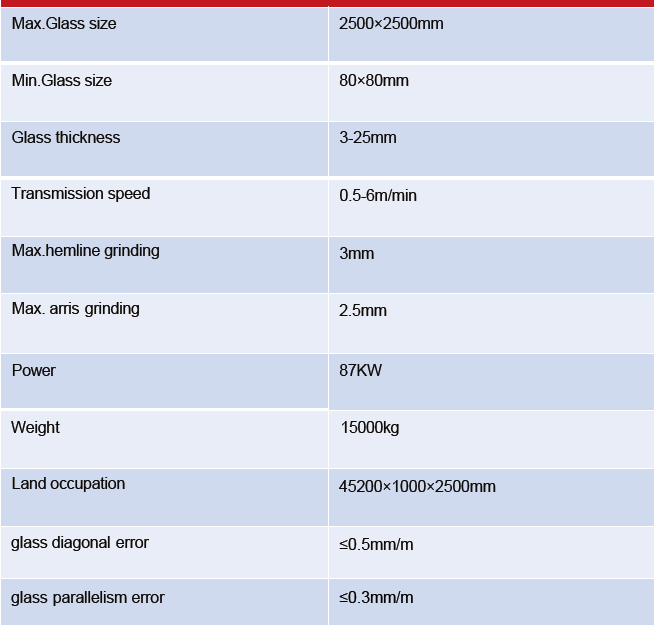

PRODUCT SPECIFICATIONS

-

Tempring Furnace Can Adopt This Force Convection System Convection Type:

1.top and bottom convection model: there are convection systems for top heating and botton heating with higt temoerature b1ower

2.top convection model: there is only convection system fior top heating with temperature bloeer

3.doulbie chamber convection type: the are two heating chamber adopts top heating convection the second one adopts radiation heatingwith air-balance. system this type for fist-quality with hight cost -

Main purpose: The machine is developed spcially for heating up low-Eglass or grass or grade domestic applianceinterior decoration vehicles,boats,curtain wall giass,etc

-

Main technical features:

pecial design of the reasonablefan makes the higt temperature capadility more reliable and ensuresexcellent effect.

The special and reasonable arrangement of the heating elements,together witch the advanced temperaturecontrol module,and PID power adjustment,make the temperature controlling extremeiy precise,adjustmenteasier and the ocen-temperature more homogenesous.

Inside the oven,we adopt high quality mater al to avoid any bits w」ich may affect the glass quality.Double betls for transmission and famous brand ceramic rollers make the running more synchronousand quality higher. The thermai circulation from the convection fan inside the oven,so the thermal losses can be avoide greatly.